Owner: Yuuki | Publication date: 2022.

Field of expertise:

Methods:

Application area:

Industry:

Temperature issues were found in the hot runner nozzle of a water injection vacuum cleaner water tank, therefore the material on the outside could not be properly solidified.

By leveraging Moldex3D’s 3D cooling simulation technology, Yuuki achieved conformal cooling design validation and overcome their molding problem, improving the success rate by 99.7%.

Challenges

- Short shots

- Poor appearance

- Long cycle time

Engineering solution

Moldex3D was used to help Yuuki validate the effectiveness of a new conformal cooling system, to reduce mold cycle times, and increase the success rate by 99.7%.

Benefits

- Achieved high-quality appearance

- Reduced cooling time by 75%

- Increase the success rate by 99.7%

- Reduced manufacturing costs

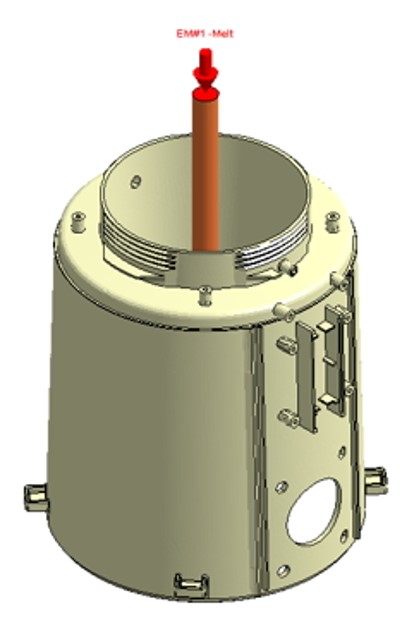

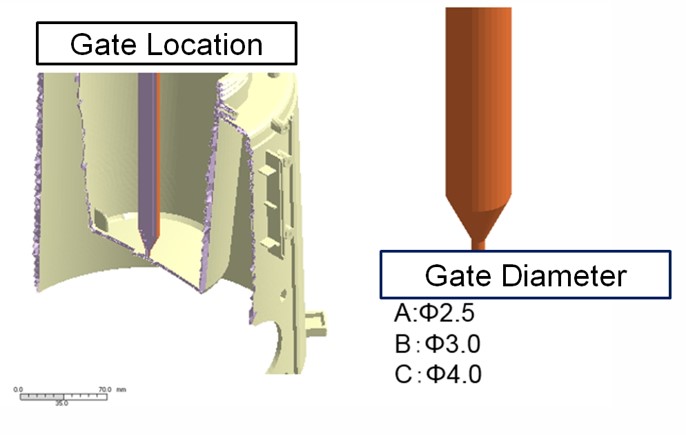

Part and runner system

Cross section of the model

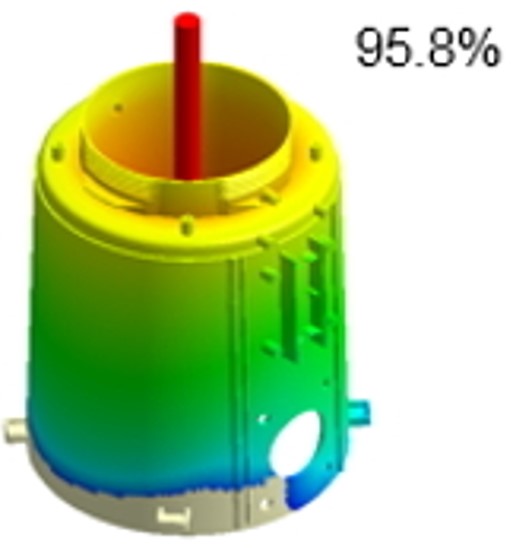

Filling of the part

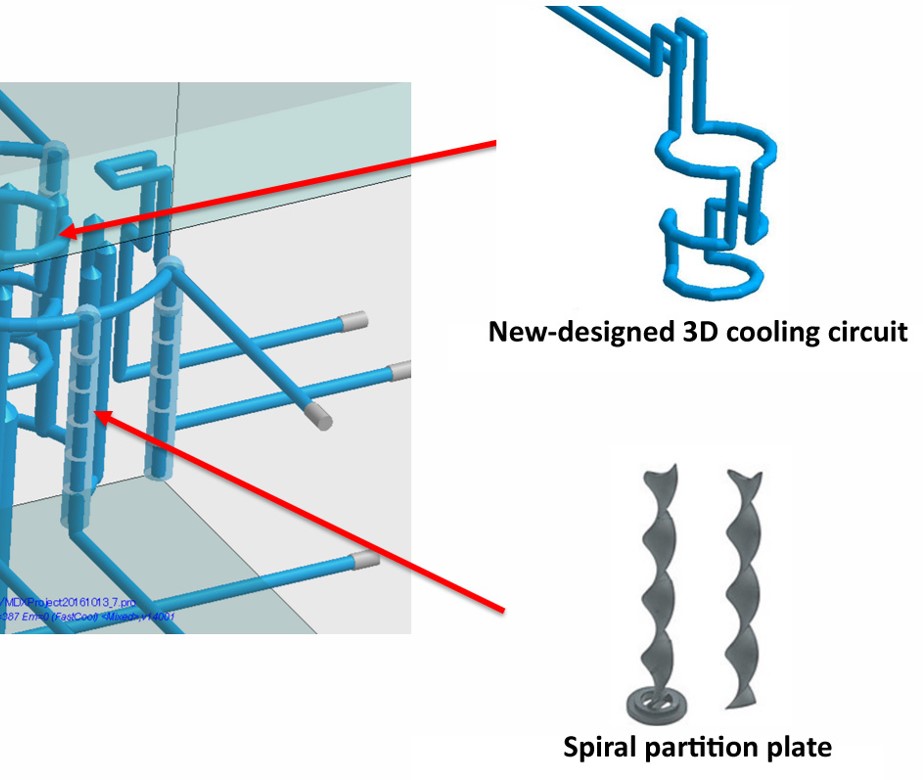

Geometry of the original cooling system

Geometry of revised cooling system

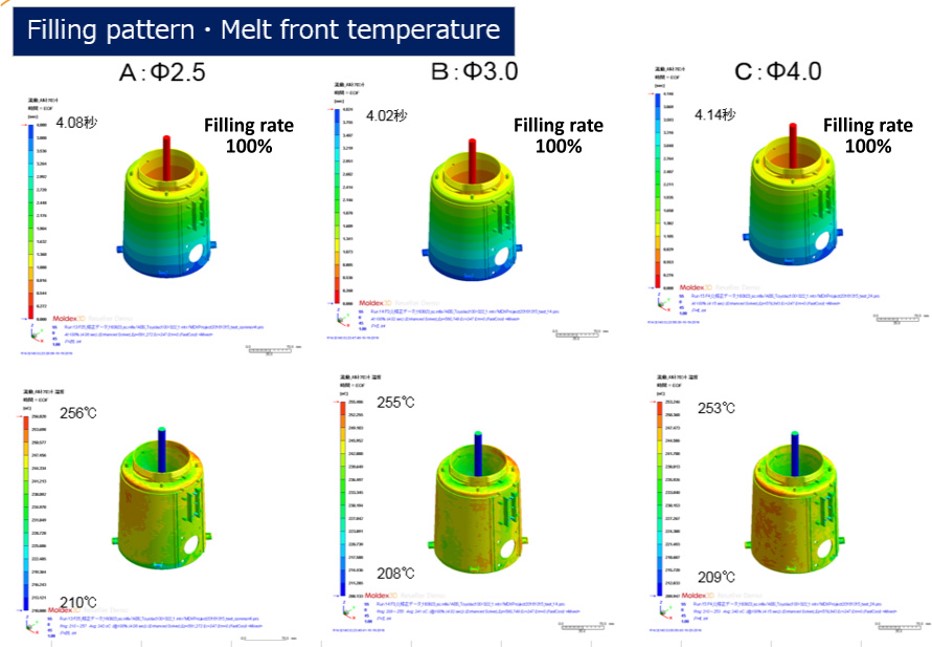

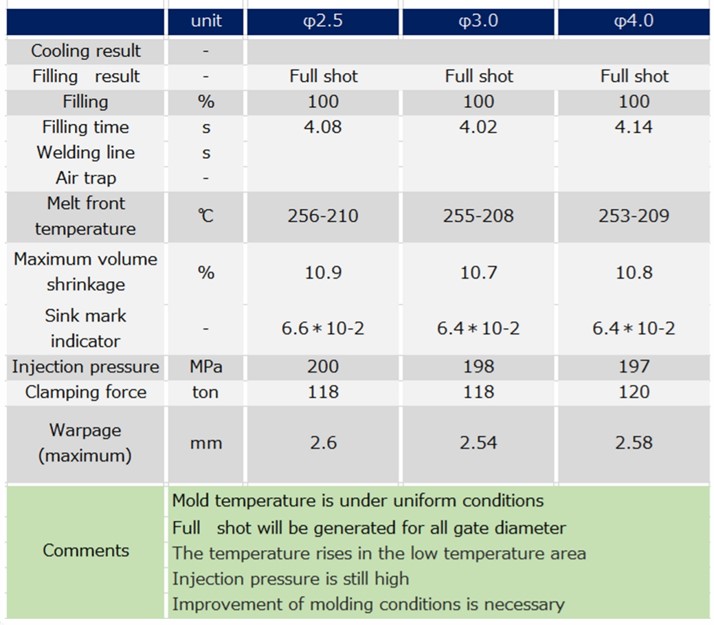

Melt front temperature distribution

Original and new results compared