Owner: Kopla | Publication date: 2022.

Field of expertise:

Methods:

Application area:

Industry:

To reduce the cooling time of thermostat housing and help customers inject the part with optimized injection parameters and cooling lines.

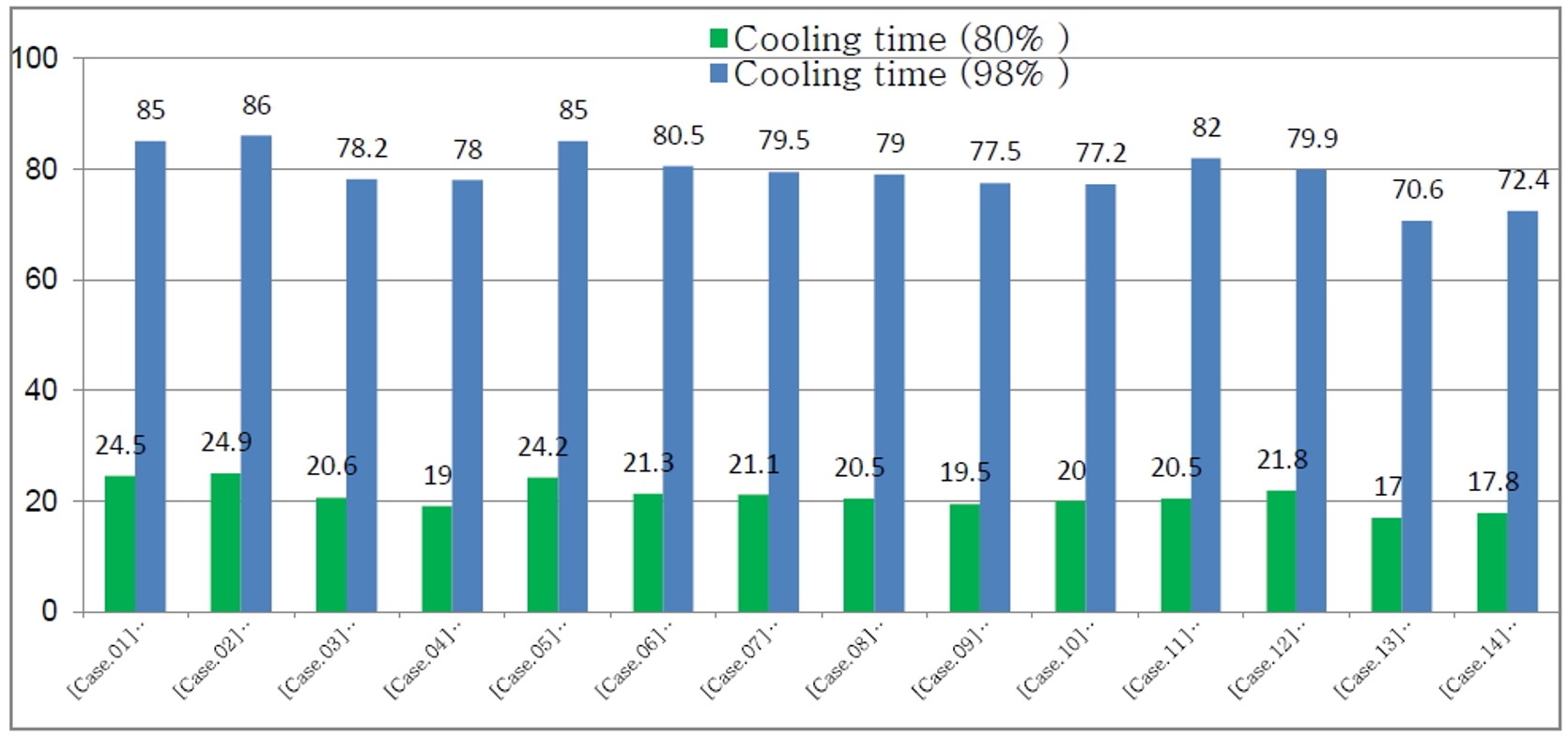

Moldex3D cooling analysis first pointed out that the required cooling time was overestimated in the original setting.

Moldex3D also helped to validate the revision on the core material and cooling line to reduce the required cooling time.

Challenges

- To achieve cooling time reduction.

- To help customer inject the part with optimized molding parameters and cooling lines.

Engineering solution

Utilizing the machine mode analysis of Moldex3D for more realistic approach of the real case and running Moldex3D cooling analysis to estimate the actual required cooling time.

Benefits

- Cooling time reduction from 85 sec to 28 sec by running Moldex3D cooling analysis successfully

- Machine mode interface can match the customer’s environment for realistic analysis results

- Understand the influences of parameter changes

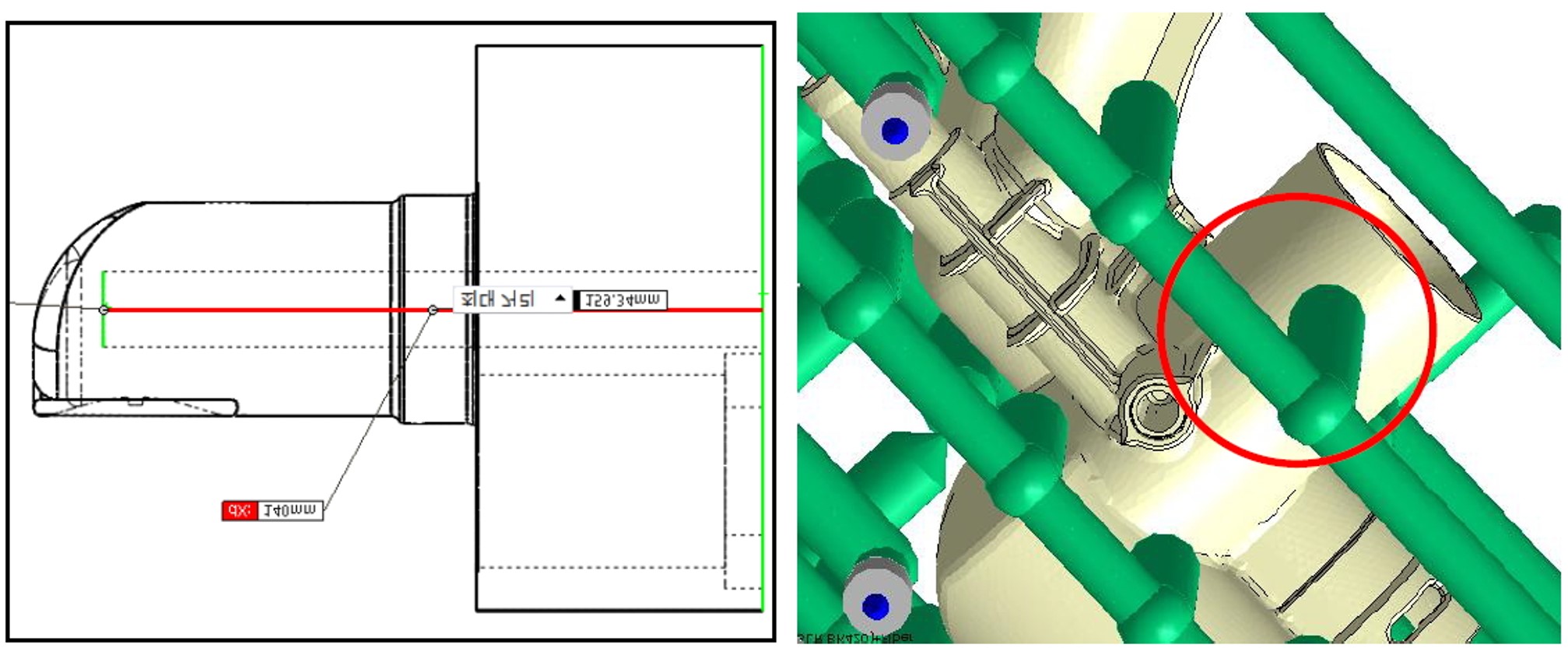

Position and cross section of baffles

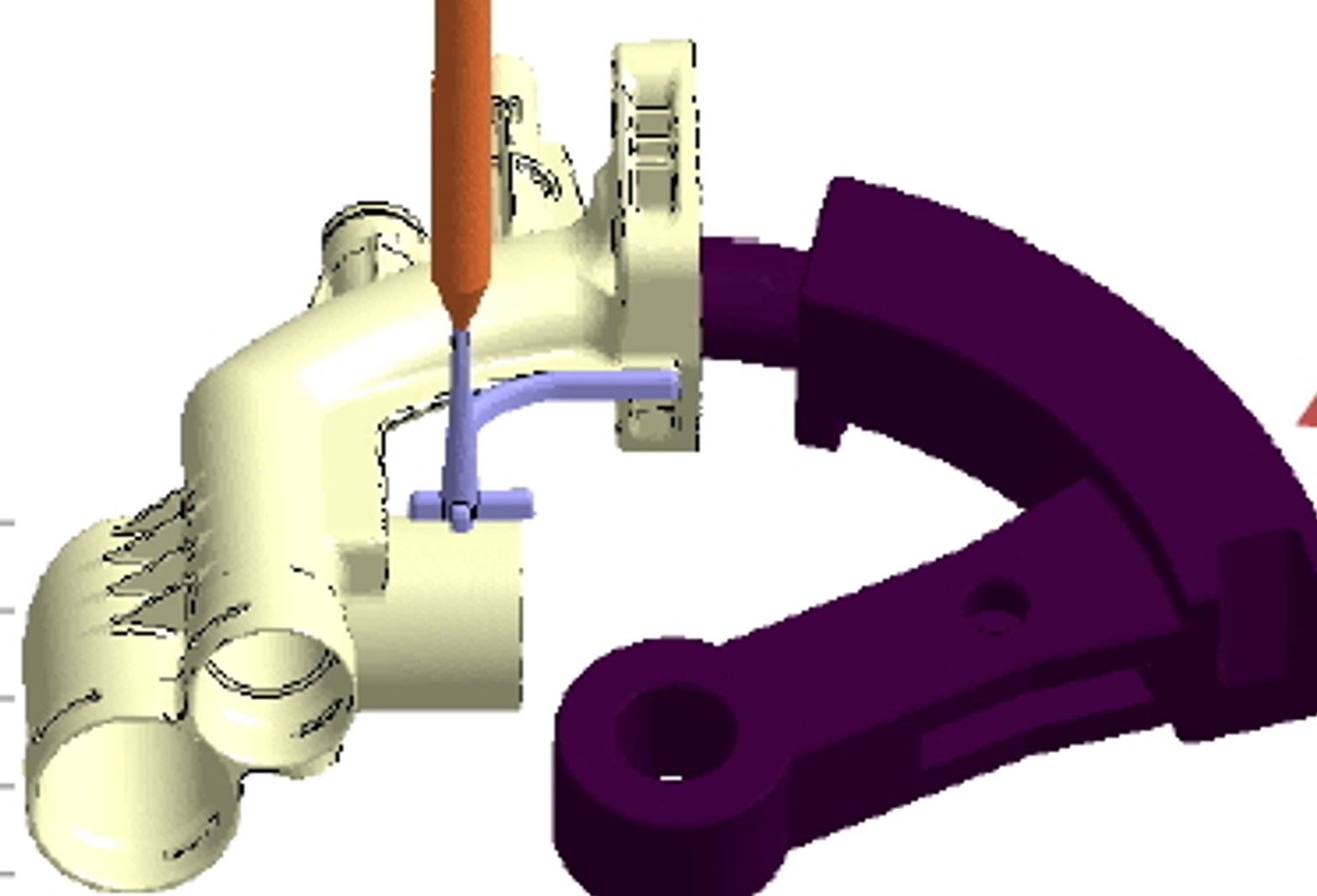

Position of part and insert

Changes in cooling time